√ Solving on-site first-in, first-out and Error Proof issues.

√ Real-time and accurate control of the operation status of the factory site for accurate and rapid decision support.

√ Automatically collecting and counting all kinds of data on site, reducing manual statistics to improve accuracy.

√ Real-time automatic calculation and provision of work-in-process inventory improve production efficiency and

reduce inventory. To improve quality control capabilities by implementing product lot traceability.

MES effect provided by MESA

1. Shortening the production cycle: 45% average reduction

2. Shortening input time: 75% average reduction

3. Reducing WIP: 17% average reduction

4. Reducing shift handover document: 56% average reduction

5. Reducing production time: 27% average reduction

6. Improving quality of products: 32% average reduction

※ MESA(Manufacturing Execution System Association) International

Instruction of Products

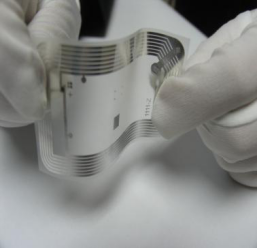

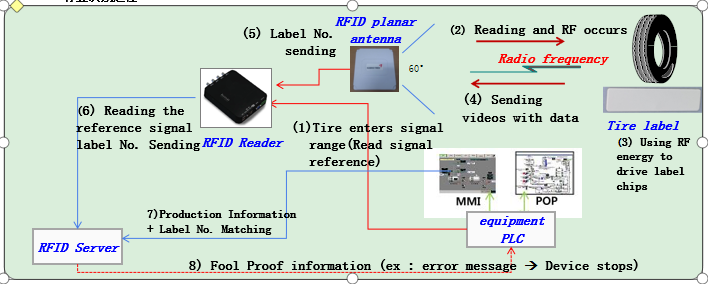

RFID(Radio Frequency Identification) is a technology to achieve data access without contact through radio waves.

The RFIDidentification system is to connect the database system through wireless communication and data access

technology to form a huge data volume and wide geographical distribution system. A complete RFID system includes

readers, electronic labels (antennas, chips) and information management systems.

Technical advantages of RFID

1. quick scan

2. Small in size and diverse in shape

3. Good pollution resistance and durability

4. Reusability

5. Penetrability and barrier-free reading

6. RFID label data can be encrypted and storage data is of large capacit.

Introduction of Tire Labels

1. quick scan

2. Small in size and diverse in shape

3. Good pollution resistance and durability

4. Reusability

5. Penetrability and barrier-free reading

6. RFID label data can be encrypted and storage data is of large capacit.

Introduction of Tire Labels

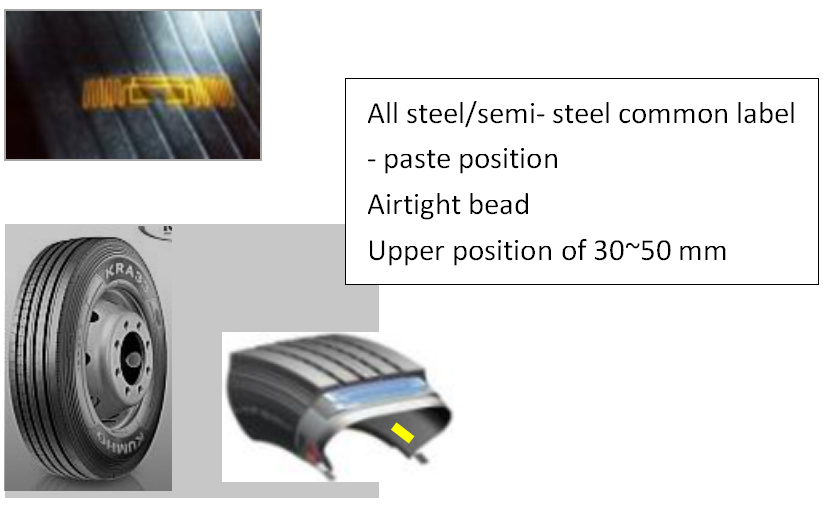

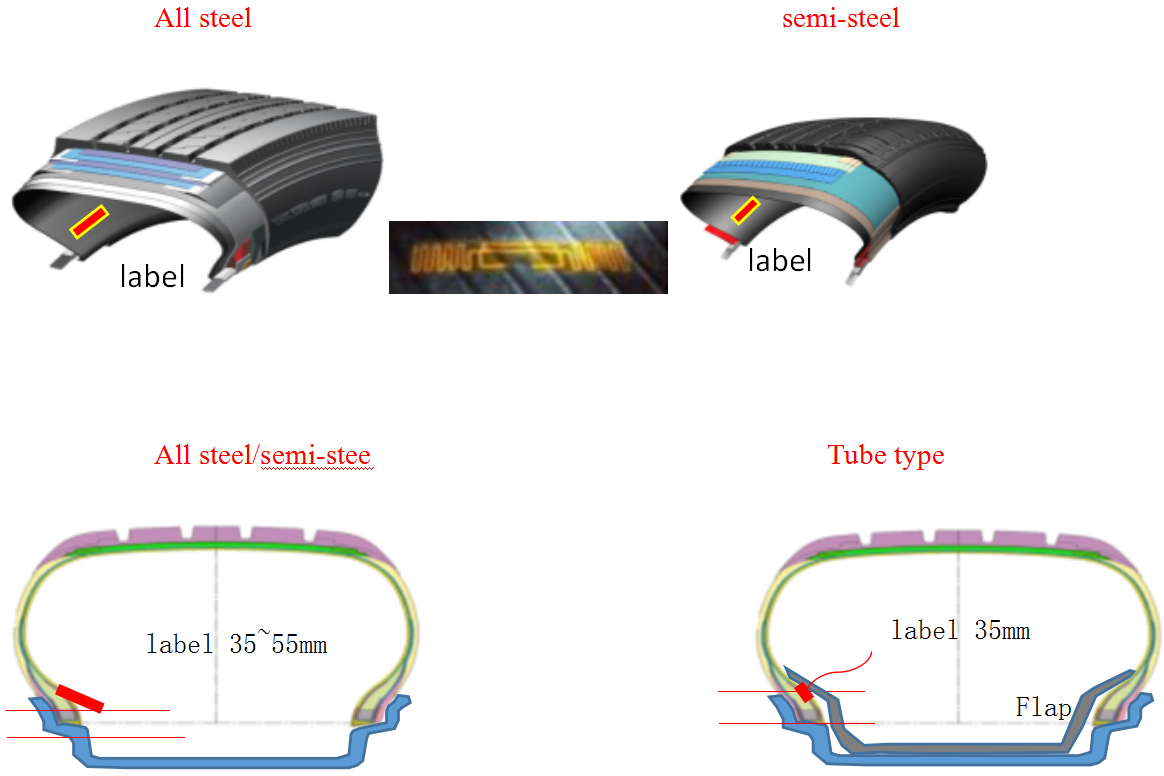

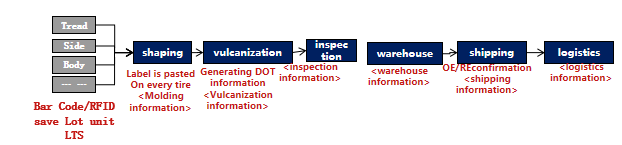

RFID tag pasting

Maximum reading record

All steel / semi-steel: 1.5 / 3.5m

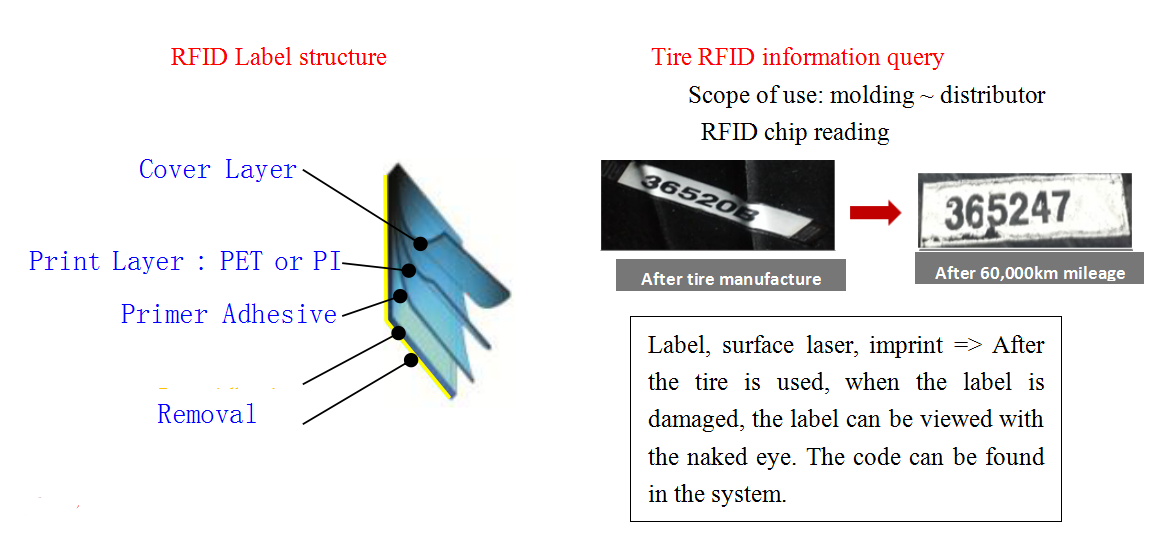

Item | Tyre RFID Label sizes | Item | Tyre RFID Label sizes | |

Label type | flaky RFID label | Inner structure | 14˚F ~ 392˚F (-10˚C ~ 200˚C) | |

Label chip | Alien Higgs-4 (EPC Memory 128bit, User Memory 128 bit) | Recognition distance | 3.9inch ~ 197inch (250px ~ 5m) | |

Radio frequency | 840 ~ 960 MHz | code appearance | Laser imprint | |

protocol | ISO/IEC 18000-6C EPCGlobal C1/G2 | The only number | 24-digit number, hex | |

size | 43.0 × 9.0 mm | |||

Tire Label Coding And Identification

# Encoding process

RFID label encoder & laser printing Laser detection and printing

|

Label No. Print, Code, Lock

(Tag memory lock)

Tip Memory

#RFID label Identification Process

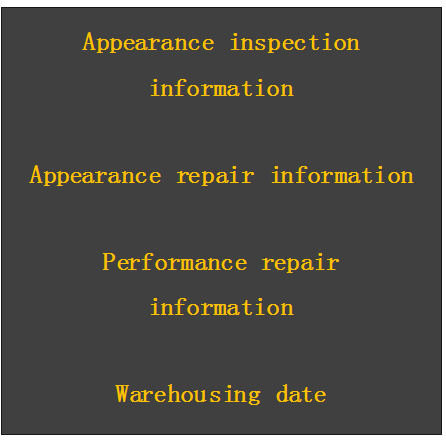

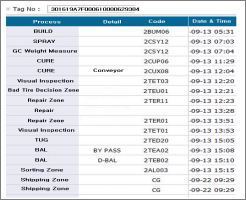

# Label No. Data Management:

Saving the engineering data of each tag in the DB, and using the label number to read the data.

other information

Information of single Tire Lot (label No benchmark)

Real-time Lot tracing

Display of Tire Label Application